How Salt Inhalers Are Made: A Step-by-Step Guide to the Craftsmanship Behind This Natural Wellness Tool

Salt inhalers have become a popular wellness device, widely used for their potential benefits in improving respiratory health, alleviating allergy symptoms, and promoting overall well-being. But have you ever wondered how these small but powerful devices are made? The process behind crafting a salt inhaler is a mix of careful material selection, skilled craftsmanship, and design, all working together to create a natural and effective wellness tool.

In this article, we’ll take you through the step-by-step process of how salt inhalers are made, from sourcing the materials to the final assembly, and why the quality of these components plays a crucial role in their effectiveness.

Step 1: Sourcing the Salt

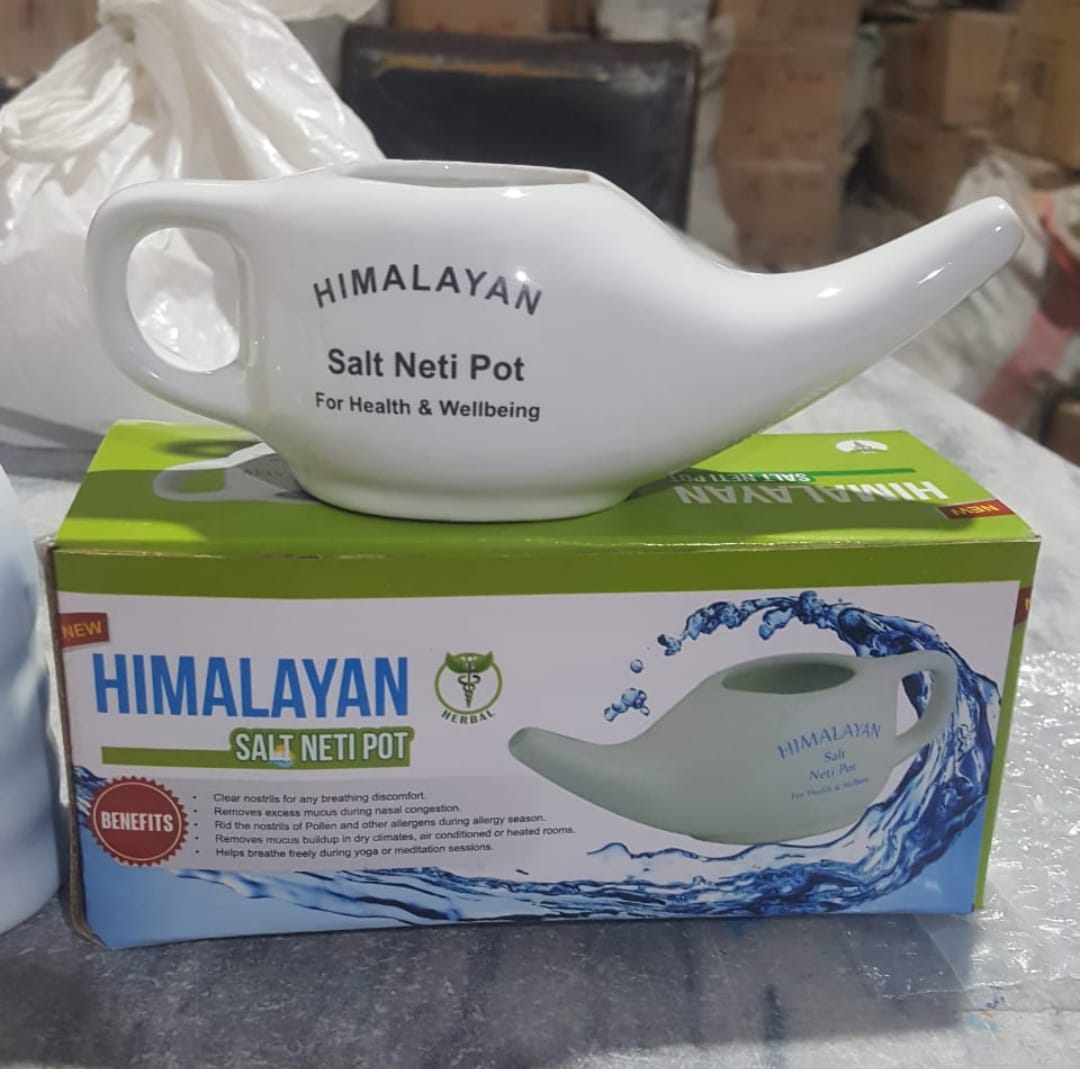

The first and most crucial step in the manufacturing of a salt inhaler is sourcing the right kind of salt. The salt used in most salt inhalers is Himalayan pink salt due to its purity and natural mineral content. Himalayan salt is hand-mined from ancient salt deposits found deep within the Himalayan mountains.

The salt crystals used for inhalers are typically larger than the fine grains used for cooking. This ensures that the salt particles are large enough to create an optimal flow of air but fine enough to be easily inhaled.

Why Himalayan Salt?

Himalayan salt is rich in essential minerals like potassium, magnesium, and calcium, which are beneficial for the body. These minerals are thought to provide therapeutic effects when inhaled. Salt inhalers made from this type of salt help create the perfect environment for natural breathing therapy, allowing the salt particles to travel deep into the lungs.

Step 2: Shaping the Salt Crystals

Once the Himalayan salt is sourced, it is carefully shaped to fit inside the inhaler. The salt crystals are sometimes processed into smaller chunks or crushed to a specific size. These crystals are not ground into a fine powder because fine salt would be too small for effective inhalation. Instead, they are left in larger, irregular pieces that allow air to pass through them as the user inhales.

How It Affects the Inhalation Process

The size and texture of the salt crystals are important because they affect the way air flows through the inhaler. The crystals need to be large enough to prevent clogging while still allowing air to pass through and pick up the tiny salt particles. This balance is key to ensuring the device’s effectiveness in delivering salt to the lungs.

Step 3: Crafting the Inhaler Body

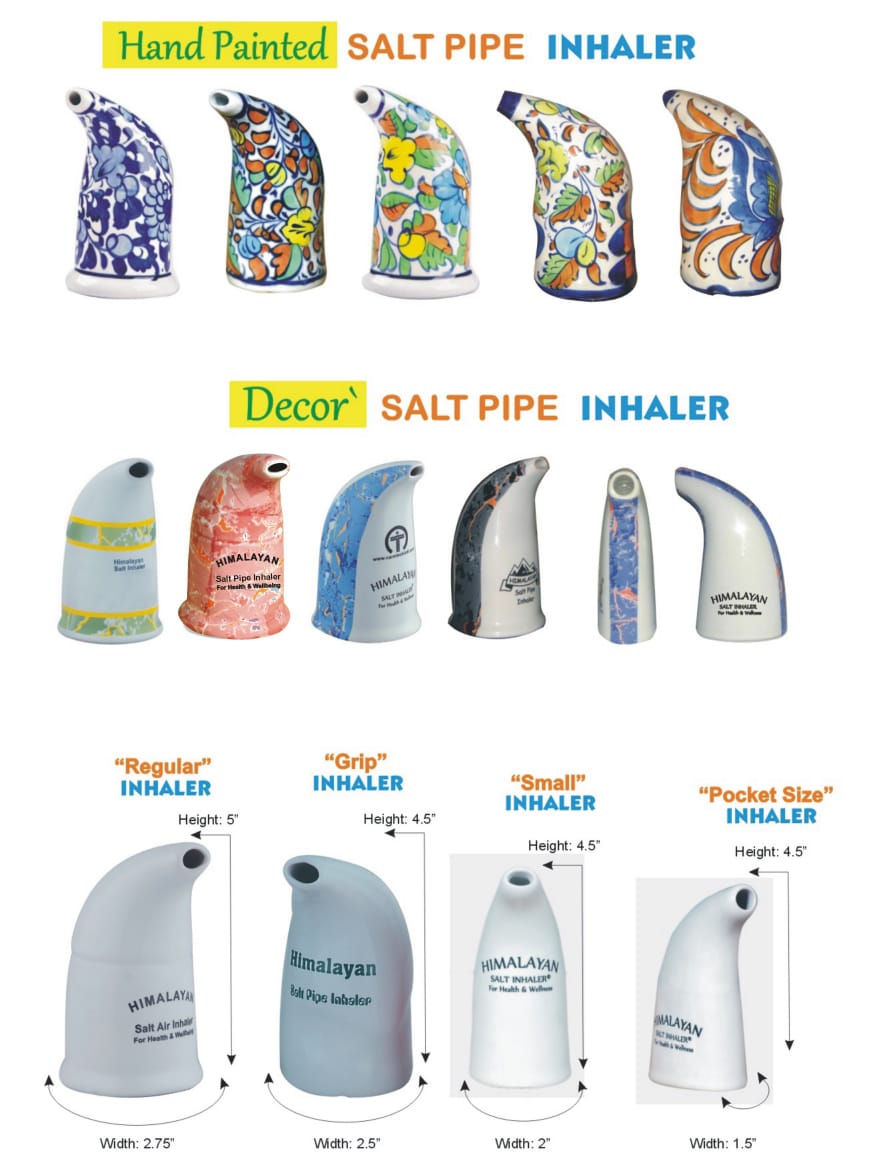

The body of a salt inhaler is typically made from materials like ceramic, plastic, or bamboo. These materials are selected for their durability, ease of use, and ability to withstand the natural moisture and wear that may come with regular use.

-

Ceramic is a popular choice because it’s non-toxic, durable, and able to withstand heat, ensuring that the inhaler lasts longer.

-

Plastic is lightweight and often used in more affordable versions of salt inhalers. It is typically BPA-free and safe for long-term use.

-

Bamboo inhalers are becoming increasingly popular due to their eco-friendly nature and the fact that bamboo is a renewable resource.

Each inhaler is meticulously designed to ensure that it is comfortable to hold and easy to use. The body must also be lightweight enough to carry around, making portability a key feature.

Step 4: Assembling the Inhaler

Once the body and salt crystals are ready, the inhaler is assembled. Here’s a typical assembly process:

-

Loading the Salt: The carefully shaped Himalayan salt crystals are placed inside the chamber of the inhaler. This step is done manually to ensure that the right amount of salt is used. The salt chamber is often designed to be refillable, so the user can add fresh salt when necessary.

-

Attaching the Mouthpiece: The mouthpiece is carefully attached to the body of the inhaler. This part is important because it allows the user to create a seal and inhale effectively. The mouthpiece must be ergonomic and comfortable to use for extended periods.

-

Final Assembly: Once the salt chamber and mouthpiece are in place, the inhaler is checked for any imperfections. Any sharp edges are smoothed out, and the inhaler is given a final cleaning to ensure it’s hygienic and ready for use.

Step 5: Quality Control and Testing

Before the salt inhalers are packaged and shipped out, they undergo a rigorous quality control process. This is essential to ensure that each inhaler functions correctly and is free from defects. The inhalers are tested for:

-

Airflow: The inhaler must allow a smooth flow of air while also ensuring that enough salt particles are drawn in with each breath.

-

Comfort: The mouthpiece is checked to make sure it is comfortable and easy to use.

-

Durability: The inhaler is subjected to a series of tests to ensure it can withstand regular use without breaking or degrading.

-

Aesthetic Quality: Since many users appreciate an aesthetically pleasing design, salt inhalers are also inspected for their appearance, ensuring that they look as good as they function.

Step 6: Packaging and Shipping

Once the salt inhalers pass quality control, they are cleaned and carefully packaged. The packaging is often designed to protect the inhaler during shipping while also showcasing its natural, eco-friendly features. Many salt inhalers are packaged with simple, recyclable materials to appeal to eco-conscious consumers.

The inhalers are then shipped to retailers, wellness shops, or directly to customers, ready to be used for natural salt therapy.

Why Does Quality Matter?

The quality of the materials used in a salt inhaler is crucial because it affects both the effectiveness and safety of the device. Inferior materials can compromise the airflow, making the inhalation process less efficient. Poor-quality salt can also affect the therapeutic benefits, as impure salts may contain additives or impurities that interfere with the salt therapy experience.

High-quality salt inhalers provide a better, more consistent experience, ensuring that users receive the maximum benefits from each session. Whether you’re using the inhaler to improve respiratory health, ease allergy symptoms, or simply promote general well-being, a well-made salt inhaler can make all the difference.

Conclusion: The Art and Science of Crafting Salt Inhalers

The making of a salt inhaler is a meticulous process that combines the art of craftsmanship with the science of wellness. From selecting the highest quality Himalayan salt to carefully assembling the inhaler and ensuring that every component is functional and durable, each step plays a vital role in creating a device that can help support natural breathing therapy.

As consumers become more aware of the benefits of salt therapy, the demand for high-quality salt inhalers continues to rise. By understanding the production process behind these devices, users can appreciate the thought and care that goes into making these simple yet effective wellness tools.

Whether you’re new to salt therapy or a seasoned user, knowing how your salt inhaler is made can deepen your appreciation for its benefits and inspire you to make the most of this natural, holistic wellness device.

For More Information Click Here